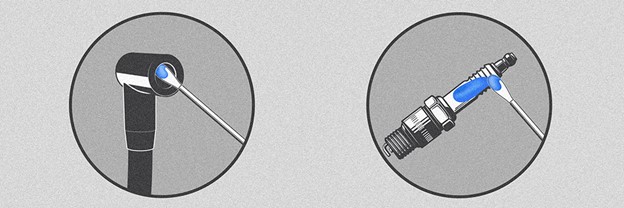

How to Apply Spark Plug Boot Protector: Easy Steps for Lasting Protection

If you want to keep your engine running smoothly and avoid costly repairs, protecting your spark plug boots is a smart move. Applying a spark plug boot protector might sound simple, but doing it the right way makes all the difference.

This little step helps stop moisture, heat, and dirt from causing misfires or damaging your spark plug connections. In this guide, you’ll learn exactly how to apply spark plug boot protector easily and effectively, so your ignition system stays reliable and your engine performs at its best.

Keep reading to discover the simple tricks that save you time and money down the road!

Credit: mgchemicals.com

Role Of Spark Plug Boot Protector

The spark plug boot protector plays an essential role in maintaining your engine’s performance. It protects the spark plug boots from damage and ensures a strong electrical connection. This small application prevents many common problems related to spark plugs. Understanding its role helps you apply it correctly and keep your vehicle running smoothly.

Preventing Boot Sticking

The boot protector stops the rubber boot from sticking to the spark plug. Heat and engine vibrations often cause the boot to bond tightly. This can make future removal difficult and may damage the boot. The protector creates a thin barrier that keeps the boot flexible and easy to remove.

Sealing Out Moisture

Moisture can cause corrosion and spark misfires. The boot protector seals out water, salt, and dirt. It creates a waterproof layer that protects the electrical connection. This seal helps keep the spark plug working properly in all weather conditions.

Stopping Voltage Arcing

Voltage arcing happens when electricity jumps to the engine block instead of flowing through the spark plug. This can cause misfires and engine problems. The boot protector acts as an insulator, stopping high voltage from escaping. This ensures the spark plug fires correctly every time.

Lubricating For Easy Removal

The protector also works as a lubricant inside the boot. It makes installing and removing the spark plug boots smoother. This reduces the risk of tearing or damaging the rubber boots during maintenance. Lubrication helps keep your spark plug boots in good shape for longer.

Choosing The Right Protector

Choosing the right spark plug boot protector is essential for engine health and performance. The correct protector prevents moisture, dirt, and corrosion from damaging the spark plug connection. It also helps avoid electrical arcing and makes future maintenance easier. Knowing the types and features of protectors helps pick the best one for your vehicle.

Silicone-based Dielectric Grease

Silicone-based dielectric grease is the most common spark plug boot protector. It resists heat and moisture well. This grease forms a barrier that stops water and dirt from entering the boot. It also prevents the rubber boot from sticking to the spark plug. This makes removal easier and protects the boot from damage.

High-temperature Formulas

High-temperature protectors work in extreme heat conditions. They keep their protective qualities even under intense engine heat. These formulas prevent the boot from melting or hardening. Use these if your engine runs very hot or if you live in a hot climate. They ensure long-lasting protection for spark plug boots.

Single-use Pouch Vs Tube

Single-use pouches offer easy and clean application. They provide the right amount of grease for one spark plug boot. Tubes allow more control over how much grease you use. Tubes are better for multiple spark plugs or repeated use. Choose the packaging style that fits your repair needs and budget.

Tools And Materials Needed

Gathering the right tools and materials makes applying a spark plug boot protector easier and more effective. Using proper items ensures a clean application and protects your spark plugs well. Prepare everything before you start for a smooth process.

Dielectric Grease Or Protector Fluid

Choose dielectric grease specially made for spark plug boots. This silicone-based grease prevents moisture and corrosion. It also stops electrical arcing and helps boots slide on easily. Apply a small amount inside the boot for best results.

Cotton Swabs Or Applicators

Use cotton swabs or small applicators to spread the grease evenly. They help reach tight spots inside the boot without mess. Avoid using fingers to keep the application clean and precise.

Protective Gloves

Wear protective gloves to keep your hands clean and avoid grease on your skin. Gloves also protect against dirt and chemicals. Use disposable gloves for easy cleanup after the job.

Credit: www.reddit.com

Preparing For Application

Preparing your spark plug wires and boots before applying a spark plug boot protector is crucial. Proper preparation ensures the protector works effectively and extends the life of your spark plugs. Follow simple steps to get the best results.

Disconnecting Spark Plug Wires

Start by gently pulling the spark plug wires off the plugs. Grip the boot, not the wire, to avoid damage. Twist the boot slightly if it feels stuck. Pull straight out to disconnect safely. Keep track of each wire to connect them correctly later.

Cleaning Boot And Terminal Surfaces

Use a clean cloth to wipe dirt and grease from the boots. Check the metal terminals inside the boots for corrosion or dirt. Clean terminals with a small wire brush or sandpaper if needed. Make sure all surfaces are dry before applying the protector. Clean parts help the protector stick and seal better.

Applying The Protector

Applying the spark plug boot protector is a simple but important step. It helps keep the spark plug boot in good condition. The protector prevents moisture, dirt, and heat damage. It also makes future removal easier. Follow these tips to apply the protector correctly.

Where To Apply Inside The Boot

Apply the protector inside the spark plug boot. Focus on the area that touches the metal terminal and porcelain part of the spark plug. This spot needs protection from moisture and corrosion. Avoid putting the protector outside the boot or on other engine parts. The inside of the boot is the key area for sealing and lubrication.

Amount To Use For Best Results

Use a small amount of protector for best results. A thin, even layer is enough to coat the inside. Too much grease can cause dirt buildup or interfere with the spark plug connection. Use a cotton swab or your finger to spread the protector evenly. Just enough to cover the contact area will work well.

Avoiding Application On Threads

Do not apply the protector on the spark plug threads. The threads need a clean surface for a tight fit. Grease on the threads can cause loose fitting or misfires. Keep the protector only inside the boot, away from the threaded part. This keeps the spark plug secure and working properly.

Installing The Boot

Installing the spark plug boot protector correctly is vital for engine performance. It ensures a strong connection and prevents damage. The process involves carefully placing the boot over the spark plug and making sure it fits well.

Sliding The Boot Onto Spark Plug

Start by holding the boot protector gently. Align it with the spark plug’s top. Slide the boot straight down without twisting. Avoid forcing it to prevent damage. The protector should glide smoothly over the spark plug.

Ensuring Proper Seating

Push the boot down until it reaches the spark plug base. It must cover the metal terminal fully. Check for gaps or uneven areas. Proper seating stops moisture and dirt from entering. This protects the connection from corrosion and wear.

Checking For Secure Fit

After seating, gently tug the boot to test its hold. It should not slide off or move easily. A secure fit keeps the boot in place during engine vibrations. This prevents electrical problems and maintains spark plug performance.

Maintenance Tips

Proper maintenance of your spark plug boot protector ensures long-lasting engine performance. Regular care keeps the protector effective against heat and moisture. Follow these simple tips to maintain your spark plug boots in top condition.

Regular Inspection

Check your spark plug boots every few months. Look for cracks, dryness, or dirt buildup. Clean the boots gently with a cloth if needed. Early detection of damage prevents engine misfires. Inspection saves time and repair costs later.

Reapplication Frequency

Reapply the boot protector after every spark plug change. For high-use vehicles, apply every 10,000 miles. Use a small amount to avoid excess grease buildup. Proper reapplication keeps boots flexible and seals out moisture.

Avoiding Common Mistakes

Do not apply the protector on spark plug threads or electrodes. Use only inside the rubber boot where it meets the plug. Avoid overapplying, which can attract dirt and cause slipping. Always clean the boots before reapplying the protector.

Common Questions

Many people have questions about using a spark plug boot protector. Understanding its purpose and proper use helps avoid mistakes. This section answers common questions clearly and simply. It covers the protector’s effect on spark performance, its use on battery terminals, and the difference between anti-seize and dielectric grease.

Does Protector Improve Spark Performance?

The protector does not increase spark power or strength. Its main job is to protect the spark plug boot from heat and moisture. It stops voltage leaks that cause misfires. This helps the spark plug work reliably. It also prevents the boot from sticking to the spark plug, making maintenance easier.

Can It Be Used On Battery Terminals?

Using spark plug boot protector on battery terminals is not recommended. It is designed to insulate high voltage in spark plug boots only. For battery terminals, use grease made for electrical connections. This type prevents corrosion and ensures good contact without causing damage.

Difference Between Anti-seize And Dielectric Grease

Anti-seize is a metal-based lubricant. It prevents parts from sticking due to rust or heat. Use it on spark plug threads only, never inside the boot. Dielectric grease, like spark plug boot protector, is silicone-based. It insulates and seals electrical connections inside the boot. Both have different jobs and should not be swapped.

Credit: www.youtube.com

Frequently Asked Questions

Do Spark Plug Boot Protectors Work?

Spark plug boot protectors, a type of dielectric grease, prevent moisture, arcing, and sticking. They protect connections and ease boot removal. Apply inside the boot, not on threads. Proper use improves spark plug life and engine performance.

Where Do You Put Spark Plug Boot Grease?

Apply spark plug boot grease sparingly inside the rubber boot where it contacts the spark plug terminal. Avoid threads and battery terminals.

Is Spark Plug Boot Protector Dielectric Grease?

Yes, spark plug boot protector is a type of dielectric grease. It prevents moisture, arcing, and sticking inside the boot.

How To Put Boot On Spark Plug Wire?

Push the boot firmly onto the spark plug wire until it snaps or fits snugly. Apply dielectric grease inside the boot for easier installation and protection. Ensure the boot covers the metal terminal completely to prevent moisture and arcing. Avoid applying grease on spark plug threads.

Conclusion

Applying a spark plug boot protector helps keep your engine running smoothly. It prevents moisture, dirt, and corrosion from causing problems. Use a small amount inside the boot for best results. This simple step makes removing boots easier later. Protecting spark plug boots extends their life and improves engine performance.

Remember, avoid putting grease on spark plug threads. Following these tips ensures a strong, safe connection every time. Spark plug boot protectors are a small investment with clear benefits. Give your vehicle the care it deserves with this easy process.