Are Jeeps Made in America: Discover the Truth Behind the Brand

Are you curious whether your Jeep is truly made in America? Jeep is a brand that many of us associate with rugged American spirit and adventure.

But with global manufacturing becoming the norm, you might wonder where exactly these iconic vehicles are built. Are Jeeps still produced on American soil, or has much of the manufacturing moved overseas? You’ll discover the real story behind Jeep’s production—where the key assembly plants are, what parts come from abroad, and how much of your Jeep is genuinely American-made.

Keep reading to get the full picture and understand what “Made in America” really means for your Jeep.

Jeep’s American Plants

Jeep has a strong manufacturing presence in the United States. Several plants across the country build Jeep vehicles. These American factories contribute significantly to Jeep’s production and heritage.

Each plant has a unique role. They focus on different models and assembly tasks. This spread supports Jeep’s ability to meet demand and maintain quality.

Toledo Factory Highlights

The Toledo factory in Ohio is one of Jeep’s oldest plants. It mainly builds the Wrangler and Gladiator models. These vehicles are famous for off-road capability.

The plant uses advanced tools and technology. This helps keep production efficient and precise. Many parts are made locally to support the factory.

Detroit Assembly Lines

Detroit hosts assembly lines that build the Grand Cherokee models. This includes the popular Grand Cherokee and Grand Cherokee L. The plant focuses on luxury and performance.

Workers here pay close attention to detail. They ensure each vehicle meets high standards. Detroit’s long history in car making supports Jeep’s craftsmanship.

Belvidere And Warren Roles

The Belvidere plant in Illinois produces the Cherokee. It handles complex assembly tasks and quality checks. Belvidere plays a key role in Jeep’s SUV lineup.

Warren, Michigan, focuses on larger models like the Wagoneer and Grand Wagoneer. These vehicles combine size with luxury features. Warren’s plant uses modern equipment to keep quality high.

Credit: jed-co.com

Global Jeep Production

Jeep is a brand known worldwide for its rugged and reliable vehicles. Its production extends beyond the United States. Jeep operates several factories across the globe. This global presence helps meet demand in different markets. It also allows Jeep to adapt to regional preferences and regulations.

Mexican Assembly Operations

Mexico plays a key role in Jeep’s manufacturing strategy. The Toluca plant assembles popular Jeep models. These vehicles often serve markets in North and South America. Mexican assembly helps reduce costs and speeds delivery. The country’s skilled workforce supports high-quality production standards.

European Facilities In Italy

In Italy, Jeep maintains assembly operations to serve European customers. The Melfi plant is a central hub for Jeep in Europe. It produces models like the Jeep Renegade and Compass. Manufacturing in Italy helps Jeep meet strict European regulations. This location also allows faster distribution across the continent.

Manufacturing In Brazil, India, And China

Jeep’s presence in Brazil supports South American markets. The Goiana plant builds SUVs tailored for local preferences. In India, Jeep manufactures vehicles to meet growing demand. The Pune facility produces popular SUV models for Indian consumers. China’s assembly plants help Jeep compete in the world’s largest car market. Local production also reduces import costs and delivery times in these regions.

Stellantis And Jeep

Stellantis plays a key role in shaping Jeep’s manufacturing and identity. As Jeep’s parent company, Stellantis influences where and how Jeeps are made. The company operates on a global scale with many production sites. Jeep’s American heritage remains strong despite this global presence.

Parent Company Profile

Stellantis is a large multinational automaker headquartered in the Netherlands. It was formed by merging Fiat Chrysler Automobiles and PSA Group. The company owns many brands, including Jeep, Dodge, and Ram. Stellantis focuses on innovation and efficiency across its brands. Jeep is one of its most popular and iconic names.

Impact On Jeep Manufacturing

Stellantis manages Jeep’s production plants in the United States. Major Jeep models like the Wrangler and Gladiator are built in Toledo, Ohio. The Grand Cherokee is assembled in Detroit, Michigan. Stellantis invests in these plants to keep production competitive. This helps Jeep maintain its American manufacturing roots. Yet, Stellantis also uses plants outside the U.S. to meet demand.

Global Supply Chain

Jeep vehicles depend on parts sourced from many countries. Stellantis uses a global supply chain to get components. Some Jeep models are assembled in Mexico, Brazil, Italy, India, and China. This allows the company to serve different markets efficiently. Even Jeeps built in the U.S. contain imported parts. The global supply chain helps Stellantis balance cost and quality.

American Parts Content

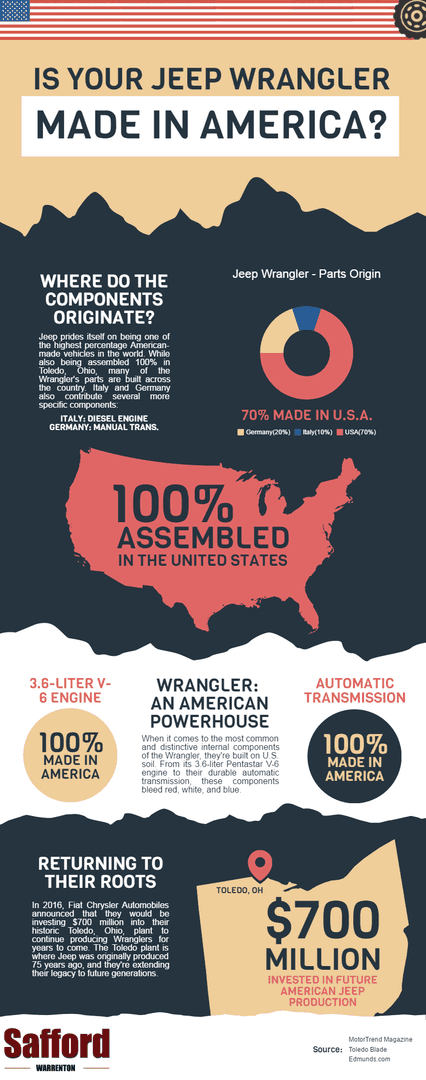

American Parts Content plays a crucial role in defining how “American” a Jeep vehicle truly is. It focuses on the origin of the parts used in the vehicle and where the final assembly takes place. Jeep vehicles often use a mix of parts sourced from the U.S., Canada, and other countries. This blend affects their ranking on American-made car lists and impacts buyer perception. Understanding the parts content helps clarify Jeep’s connection to American manufacturing.

U.s. And Canadian Component Use

Jeep uses many parts made in the U.S. and Canada. These parts include engines, transmissions, and key components. The North American Free Trade Agreement (NAFTA) region supports this supply chain. Many Jeep models contain more than 70% of parts from the U.S. and Canada by value. This high percentage helps Jeep maintain a strong American manufacturing image. Still, some parts come from other countries for cost or availability reasons.

Cars.com American-made Index

The Cars.com American-Made Index ranks vehicles by their U.S. and Canadian parts content. It also considers where the final assembly happens. Jeep models like the Wrangler and Grand Cherokee often score high on this list. These rankings help buyers identify vehicles mostly made with American and Canadian parts. The index shows that Jeep has a strong presence in the American-made vehicle market. It highlights the brand’s commitment to sourcing parts close to home.

Limits Of Fully American-made Vehicles

No vehicle is 100% American-made today. Even Jeep models assembled in the U.S. include some imported parts. Global supply chains mean manufacturers source parts worldwide. This reality sets limits on fully American-made vehicles. The cost and availability of parts influence sourcing decisions. Jeep balances American parts content with global sourcing to stay competitive. Buyers can expect many American parts but should know full domestic origin is rare.

Popular U.s.-made Jeep Models

Jeeps hold a special place in American automotive history. Many Jeep models are built in the United States. This means American workers build vehicles that reflect tough and rugged designs. Popular Jeep models like the Wrangler, Gladiator, Grand Cherokee, and Cherokee are assembled in U.S. plants. Their production keeps jobs local and supports the economy. Each model has its own story and manufacturing location.

Understanding where each Jeep is made helps buyers appreciate their value. It also shows how Jeep balances American craftsmanship with global parts. Let’s explore the origins and assembly details of these popular models.

Wrangler And Gladiator Origins

The Jeep Wrangler and Gladiator are built at the Toledo Assembly Complex in Ohio. This plant has made Wranglers for decades. The Gladiator, Jeep’s pickup truck, shares this factory. Both models represent Jeep’s rugged design and off-road capability. The Toledo plant uses advanced technology and skilled workers. This ensures each Jeep meets strict quality standards.

Wranglers are famous for their durable frames and removable tops. Gladiators combine this with truck bed functionality. Both models feature many parts made in the U.S. Their roots trace back to the original military Jeeps made in America.

Grand Cherokee Assembly Details

The Jeep Grand Cherokee is assembled at the Jefferson North Assembly Plant in Detroit, Michigan. This plant focuses on building SUVs with a mix of luxury and performance. The Grand Cherokee is one of Jeep’s best-selling models. It offers strong engines and advanced safety features.

The Detroit plant uses a mix of American-made parts and global components. Skilled workers assemble each vehicle with care. The plant has modern equipment to keep production efficient. The Grand Cherokee’s design reflects American strength and style.

Cherokee Manufacturing Insights

The Jeep Cherokee is produced at the Belvidere Assembly Plant in Illinois. This facility builds mid-size SUVs known for comfort and versatility. The Cherokee blends city driving ease with off-road ability. Belvidere uses a mix of local and imported parts.

The plant employs many local workers who specialize in automotive assembly. The Cherokee’s production emphasizes quality control. This model is popular for families and outdoor enthusiasts alike. Its U.S. manufacturing roots add to its appeal.

Credit: www.saffordofwarrenton.com

International Jeep Models

Jeep is a brand known worldwide for rugged vehicles. Not all Jeep models are made in the United States. Some are produced in other countries to meet global demand. These international Jeep models help the brand reach more customers.

Manufacturing Jeep vehicles abroad allows for cost savings and better market fit. Different models are built in specific countries. This strategy supports Jeep’s growth outside the U.S.

Compass Production Abroad

The Jeep Compass is mostly built outside the U.S. Its main production plants are in Mexico and India. These locations offer lower production costs and access to local markets. The Compass made abroad is sold in many countries, including the U.S.

Building the Compass internationally helps Jeep meet worldwide demand. It also keeps prices competitive for buyers around the globe.

Renegade’s European Roots

The Jeep Renegade is designed and built mainly in Italy. Fiat Chrysler Automobiles, Jeep’s parent company, uses its European plants for this model. The Renegade fits well with European driving styles and city roads.

Its European production supports Jeep’s presence in the continent. The Renegade is popular in Europe and other regions with similar tastes.

Global Market Targeting

Jeep manufactures different models worldwide to suit local needs. Production happens in countries like Brazil, China, and Italy. This approach reduces shipping costs and import taxes.

Global manufacturing allows Jeep to offer vehicles tailored to various markets. It also helps the brand compete with local car makers in many regions.

Jeep’s American Identity

Jeep holds a strong place in American culture. Its identity is deeply tied to the United States. Many people wonder if Jeep vehicles are truly made in America. The truth blends history and modern manufacturing.

Historical Brand Roots

Jeep was born during World War II. The U.S. military needed a tough, reliable vehicle. Jeep met that need perfectly. It became a symbol of American strength and freedom. Over decades, Jeep kept this image alive. The brand’s early designs and uses were purely American. This history shapes how people see Jeep today.

Current Manufacturing Reality

Today, many Jeep models are still built in the U.S. Key plants operate in Ohio, Michigan, and Illinois. The Jeep Wrangler and Gladiator come from Toledo, Ohio. The Grand Cherokee is made in Detroit, Michigan. The Cherokee model is built in Belvidere, Illinois. These factories employ thousands of Americans. Yet, Jeep also assembles vehicles in other countries. Mexico, Brazil, Italy, India, and China help meet global demand. Parts come from both U.S. and international suppliers. So, Jeep’s production spans continents but keeps strong American roots.

Balancing Global And Local

Jeep balances global reach with local manufacturing. It serves markets worldwide while keeping U.S. jobs. The parent company, Stellantis, is international. This means Jeep reflects a mix of global ideas and local craft. Jeep’s American identity stays alive through its U.S. plants and heritage. At the same time, the brand adapts to global needs. This balance helps Jeep remain competitive and respected.

Credit: www.saffordofwarrenton.com

Consumer Perspectives

Consumers often wonder about Jeep’s true American identity. Their views reveal a mix of pride and skepticism. Understanding these perspectives helps clarify Jeep’s place in the market. Buyers care about where Jeeps are made and the parts used. Brand loyalty plays a strong role in how people perceive Jeep’s American roots.

Is Jeep Truly American-made?

Jeep builds many models in the United States. Key plants are in Ohio, Michigan, and Illinois. These factories assemble popular models like the Wrangler and Grand Cherokee. Yet, some parts come from other countries. The parent company, Stellantis, operates globally. This mix causes debate about Jeep’s American status.

Many buyers feel Jeep remains American because of its U.S. assembly. Others focus on the global parts supply and ownership. The truth lies in a balance: Jeep is partly American-made, partly global.

Buying With American Parts In Mind

Shoppers wanting American-made vehicles look at parts content. The U.S. and Canada supply much of Jeep’s components. High parts content means more American jobs and economy support. Websites like Cars.com offer indexes ranking vehicles by American-made parts.

Choosing a Jeep with high U.S./Canadian parts helps buyers feel confident. It also supports local manufacturing. Still, no Jeep is 100% made in America. Knowing this helps buyers make informed decisions.

Navigating Brand Loyalty

Jeep has a strong, loyal fan base. Many buyers trust the brand’s rugged image and history. This loyalty often overshadows concerns about manufacturing origins. Fans value Jeep’s style, performance, and reputation.

Brand loyalty can influence how much weight buyers give to American-made status. Some accept global parts as part of modern car production. Others remain proud of Jeep’s American assembly roots. Loyalty shapes perceptions more than facts for many consumers.

Frequently Asked Questions

Are Jeeps 100% Made In The Usa?

Jeeps are largely made in the USA, with key assembly plants in Ohio and Michigan. Some models are produced internationally. Parts come from both U. S. and global suppliers, so Jeeps are not 100% American-made but maintain strong U. S.

When Did Jeep Stop Being American?

Jeep stopped being fully American when Stellantis, a multinational company, acquired it in 2021. Jeep still builds many models in the USA.

Which Jeep Models Are Made In The Usa?

Jeep models made in the USA include the Wrangler, Gladiator, Grand Cherokee, Wagoneer, and Cherokee. They assemble these in plants in Michigan, Ohio, and Illinois. Some Jeep models, like Compass and Renegade, are produced outside the U. S. for global markets.

Is There Any Vehicle 100% Made In America?

No vehicle is 100% made in America due to global parts sourcing and assembly. Some models have high U. S. content and assembly.

Conclusion

Jeeps have strong American roots and are built in U. S. Plants. Many popular models come from factories in Ohio, Michigan, and Illinois. Still, some Jeeps are made outside the U. S. For global markets. Parts often come from different countries, reflecting modern car production.

Jeep stays true to its heritage while serving a worldwide audience. This mix shows the brand’s balance between American tradition and global reach. Owning a Jeep means owning a piece of American history with global craftsmanship.