Where are Jeeps Manufactured: Discover Their Global Origins

Are you curious about where your favorite Jeep vehicles come from? Whether you own a rugged Wrangler, a powerful Gladiator, or a stylish Grand Cherokee, knowing where these iconic SUVs are made can give you a deeper connection to the brand.

Jeep has a rich history rooted in American manufacturing, but the story doesn’t end there. With plants spread across the globe, Jeep combines American tradition with international craftsmanship to deliver the quality and performance you expect. You’ll discover exactly where Jeeps are manufactured and how this global approach shapes the vehicles you drive.

Keep reading to uncover the surprising facts behind Jeep’s production and what it means for your next adventure on the road.

Credit: www.bodyshopbusiness.com

Jeep’s American Roots

Jeep has a long history deeply connected to America. The brand started during World War II, building rugged vehicles for the U.S. military. Over the years, Jeep became a symbol of American strength and adventure. Even today, many Jeep models are made in the United States, keeping its roots alive. The company combines tradition with modern manufacturing to serve drivers worldwide.

Iconic Models Made In The Usa

The Jeep Wrangler stands out as a truly American-made icon. It is built to handle tough terrains and is popular for off-road adventures. The Jeep Gladiator, a rugged pickup truck, also rolls off assembly lines in the U.S. These models showcase Jeep’s commitment to quality and durability. The Grand Cherokee, another favorite, is crafted in American factories and offers luxury with strong performance.

Key U.s. Assembly Plants

Jeep’s main manufacturing plants are located in Ohio and Michigan. The Toledo Assembly Complex in Ohio produces the Wrangler and Gladiator. This plant is known for its skilled workforce and advanced production techniques. In Michigan, the Jefferson North Assembly Plant builds the Grand Cherokee. The Warren Truck Assembly Plant makes the Wagoneer and Grand Wagoneer. These facilities play a vital role in maintaining Jeep’s American heritage.

Credit: www.saffordofwarrenton.com

Major U.s. Manufacturing Facilities

Jeep vehicles hold a strong place in American automotive history. Many of their popular models come from key U.S. factories. These plants play a vital role in building Jeeps that drivers trust. Each site focuses on different models and uses advanced technology to ensure quality and durability.

Understanding where Jeeps are made helps appreciate the craftsmanship behind each vehicle. The major U.S. manufacturing facilities are located in Ohio and Michigan. These plants not only assemble vehicles but also contribute to the local economy by providing jobs and supporting suppliers.

Toledo Assembly Complex

The Toledo Assembly Complex in Ohio is Jeep’s oldest and most famous factory. It produces the Jeep Wrangler and Gladiator. These models are known for their rugged off-road capability. The plant uses modern robotics alongside skilled workers to build strong frames and bodies. Toledo’s long history with Jeep adds authenticity to every vehicle made there.

Detroit Assembly Complex

The Detroit Assembly Complex in Michigan builds Jeep’s Grand Cherokee models. This plant focuses on luxury and performance. It combines high-quality materials with innovative manufacturing methods. The site ensures that each Grand Cherokee meets strict safety and comfort standards. Detroit’s expertise helps keep Jeep competitive in the SUV market.

Warren Truck Assembly Plant

The Warren Truck Assembly Plant in Michigan produces the Wagoneer and Grand Wagoneer. These large SUVs require precise assembly and attention to detail. The plant uses cutting-edge technology to handle complex parts and systems. Warren’s role is crucial in making Jeep’s premium vehicles reliable and stylish. It supports Jeep’s presence in the luxury SUV segment.

Global Production Sites

Jeep vehicles are built in several countries around the world. These global production sites help meet the demand for Jeep models in different markets. Each factory focuses on specific models to serve regional needs efficiently.

Manufacturing locations are chosen for their strategic benefits, such as skilled labor and access to markets. This network supports Jeep’s global presence while keeping quality high and costs manageable.

Italy’s Melfi Plant

The Melfi plant in southern Italy assembles Jeep Compass models. It serves mainly European customers. The factory uses advanced techniques to maintain high quality. It is an important site for Jeep’s expansion in Europe.

Mexico’s Toluca Factory

Mexico’s Toluca factory produces Jeep Compass vehicles. It supplies the North and Latin American markets. This location offers skilled workers and lower production costs. The plant plays a key role in Jeep’s presence in the Americas.

Brazil’s Goiana Plant

The Goiana plant in Brazil builds Jeep Renegade and Compass models. It mainly serves South American customers. This factory supports Jeep’s growth in the region with local assembly. It helps reduce shipping times and costs.

Other International Locations

Jeep also has smaller production or assembly sites in other countries. These help meet local market demand quickly. They also provide parts and support to major factories. This global network strengthens Jeep’s worldwide reach.

Model-specific Manufacturing Locations

Jeep manufactures its models in different locations worldwide. Each model has a specific plant where it is built. This strategy helps Jeep meet demand in various markets efficiently. It also allows the brand to use local resources and labor.

Wrangler And Gladiator Production

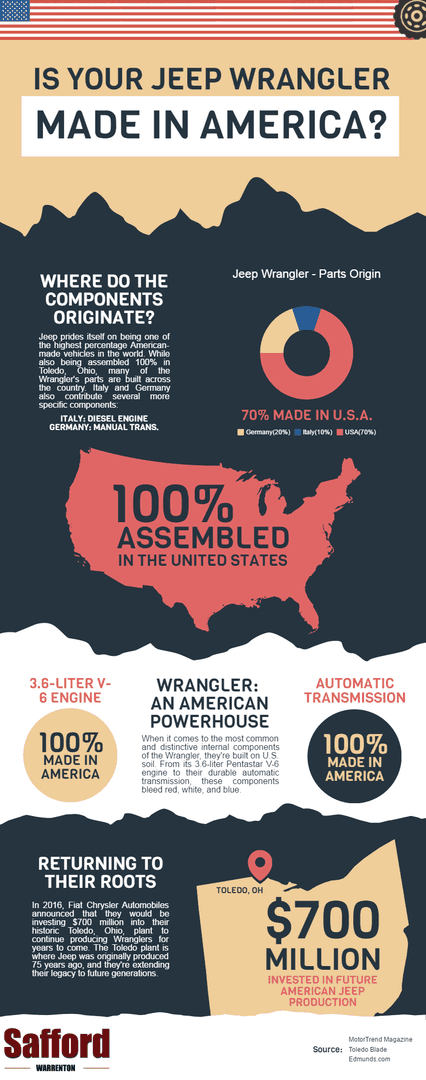

The Jeep Wrangler and Gladiator are made in the United States. Both models are assembled at the Toledo Assembly Complex in Ohio. This plant has been Jeep’s home for decades. It specializes in rugged vehicles designed for off-road performance. The Toledo facility uses advanced manufacturing techniques to maintain quality and durability.

Compass Assembly Across Borders

The Jeep Compass is built in several countries to serve global markets. In the United States, the Compass is assembled in Toluca, Mexico. European versions come from the Melfi plant in Italy. This cross-border production allows Jeep to reduce shipping costs and adapt to regional preferences. It also helps keep the Compass competitively priced worldwide.

Renegade’s Manufacturing Hubs

The Jeep Renegade is produced mainly in two locations. The primary plant is in Goiana, Brazil, which serves the South American market. Another assembly site is the Melfi plant in Italy, catering to Europe and other regions. These hubs focus on small SUV production, combining efficiency with Jeep’s signature style. Local production supports faster delivery and better customer service in these areas.

Impact Of Global Ownership

The impact of global ownership shapes Jeep’s production and brand identity. Jeep is no longer solely an American company. Its ownership and manufacturing now span several countries. This global reach affects where Jeeps are made and how the brand stays true to its roots. Understanding this influence helps clarify Jeep’s current manufacturing landscape.

Stellantis And International Influence

Jeep is owned by Stellantis, a multinational car company. Stellantis formed from a merger of Fiat Chrysler and PSA Group. This merger brought Jeep under a larger global umbrella. Stellantis manages Jeep’s production across many countries. Jeep models are built in the United States, Italy, Mexico, and Brazil. This spread helps Stellantis meet global demand efficiently. It also shares technology and resources among brands worldwide.

Balancing American Identity With Global Reach

Jeep keeps a strong American image despite global ownership. Key models like the Wrangler and Grand Cherokee are still built in U.S. plants. These vehicles maintain Jeep’s American heritage and appeal. At the same time, Jeep builds other models in international plants. This balance helps Jeep stay competitive and accessible worldwide. Jeep combines American tradition with global manufacturing strengths. The brand adapts while honoring its origins in the United States.

Future Trends In Jeep Manufacturing

The future of Jeep manufacturing is evolving rapidly. The brand focuses on expanding production and adopting new technologies. These changes aim to meet global demand and improve vehicle quality. Jeep’s manufacturing plants are becoming smarter and more efficient. The company plans to balance global reach with local expertise to stay competitive.

Expanding Global Footprint

Jeep is increasing its production presence worldwide. New factories are opening in emerging markets. This approach reduces shipping costs and delivery times. It also helps Jeep adapt to local preferences. The brand strengthens its supply chain by sourcing parts closer to assembly plants. Expansion supports Jeep’s goal to sell more vehicles internationally.

Technological Innovations In Plants

Manufacturing plants are adopting automation and robotics. These tools improve precision and speed up assembly lines. Digital systems track each vehicle’s progress in real time. Factories use data analytics to reduce errors and waste. Energy-efficient equipment lowers the environmental impact. Smart plants help Jeep produce higher quality vehicles faster and cheaper.

Credit: www.tatebranchhobbs.com

Frequently Asked Questions

Is The Jeep 100% American Made?

Jeep is not 100% American made. Popular models like Wrangler and Gladiator are made in the USA, but some are assembled globally.

Is Jeep No Longer American?

Jeep remains American, with key models like Wrangler and Gladiator made in U. S. plants. Global production supports its worldwide presence.

Which Jeeps Are Made In The Usa?

Jeep models made in the USA include the Wrangler, Gladiator, Grand Cherokee, Wagoneer, and Grand Wagoneer. They assemble mainly in Ohio and Michigan.

Is The Jeep Still Made In America?

Yes, Jeep manufactures key models like the Wrangler, Gladiator, and Grand Cherokee in the USA, mainly in Ohio and Michigan plants.

Where Are Most Jeep Vehicles Manufactured?

Most Jeep models are made in the United States. Key plants are in Ohio, Michigan, and Texas. Some production also happens abroad.

Conclusion

Jeeps are mainly made in the United States, with key plants in Ohio, Michigan, and Texas. Some models are also assembled in Mexico, Brazil, and Italy. Despite global production, Jeep keeps strong ties to its American roots. Core models like the Wrangler and Grand Cherokee proudly carry the “Made in USA” label.

This mix of locations helps Jeep serve customers worldwide. The brand blends tradition with modern manufacturing to meet demand everywhere. Jeep’s identity remains connected to its American heritage.