How to Tighten Spark Plugs Without a Torque Wrench: Easy DIY Tips

Tightening spark plugs just right is key to keeping your engine running smoothly. But what if you don’t have a torque wrench on hand?

Don’t worry—you can still get the job done safely and effectively. In this guide, you’ll learn simple, reliable ways to tighten your spark plugs without a torque wrench. Whether you’re in a pinch or just want to save time, these tips will help you avoid common mistakes like over-tightening or under-tightening, which can cause engine problems or costly repairs.

Keep reading to discover easy methods that put you in control and ensure your spark plugs are perfectly set every time.

Credit: www.densoautoparts.com

Torque Wrench Benefits

Using a torque wrench to tighten spark plugs offers clear advantages. It helps avoid common problems caused by incorrect tightening. Proper torque ensures safety and optimal engine function. Understanding these benefits explains why many mechanics prefer this tool.

Preventing Damage

Over-tightening spark plugs can strip threads in aluminum heads. This damage is costly and hard to fix. A torque wrench applies the right force, avoiding cracks in the plug’s ceramic insulator. This protects both the spark plug and engine parts.

Ensuring A Proper Seal

Correct torque compresses the crush washer or seats the plug properly. This prevents combustion gases from leaking out. A tight seal keeps engine compression steady and stops misfires. It also helps maintain engine efficiency and reliability.

Boosting Engine Performance

Properly tightened spark plugs improve heat transfer and electrical flow. This supports smooth combustion and better fuel use. Engines run cleaner and stronger with the right spark plug torque. Overall performance and fuel economy benefit from this precision.

Risks Without A Torque Wrench

Tightening spark plugs without a torque wrench carries certain risks. Getting the right tightness is important for engine health. Too much or too little force can cause problems that affect performance and safety. Understanding these risks helps avoid costly repairs and engine damage.

Over-tightening Issues

Over-tightening spark plugs can damage the threads in the cylinder head. This damage may cause stripping, which is expensive to fix. The spark plug’s ceramic insulator can also crack under too much pressure. Cracks lead to misfires and poor engine performance. Over-tightening can also break the spark plug, requiring a full replacement. The aluminum cylinder head is especially sensitive to excess force and can crack or warp.

Under-tightening Problems

Under-tightening spark plugs can cause combustion gases to leak. This leakage lowers engine compression and reduces power. Loose plugs can cause misfires and poor fuel economy. They may also cause the engine to run roughly or stall. If a spark plug is too loose, it can vibrate and damage the threads. This problem may lead to costly repairs or replacement parts.

Hand Tightening Techniques

Tightening spark plugs without a torque wrench requires care and attention. Hand tightening techniques help prevent damage to the threads and ensure a proper seal. Using your hands allows you to feel when the spark plug seats correctly. This method reduces the risk of over-tightening or under-tightening.

Proper hand tightening keeps the spark plug secure and helps the engine run smoothly. The key is to screw in the plug gently at first and then add the right amount of turn to seal it. Follow these simple steps to tighten spark plugs safely without a torque wrench.

Seating The Spark Plug By Hand

Start by placing the spark plug into the hole carefully. Use your fingers to turn the plug slowly. This helps avoid cross-threading, which can damage the threads. Turn the plug until you feel resistance, which means it has seated firmly. Do not force it. If the plug does not screw in easily, back it out and try again to avoid damage.

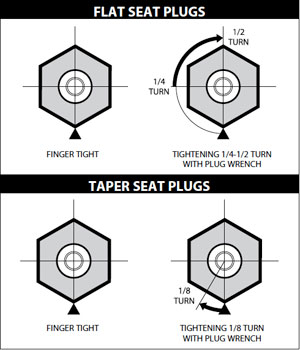

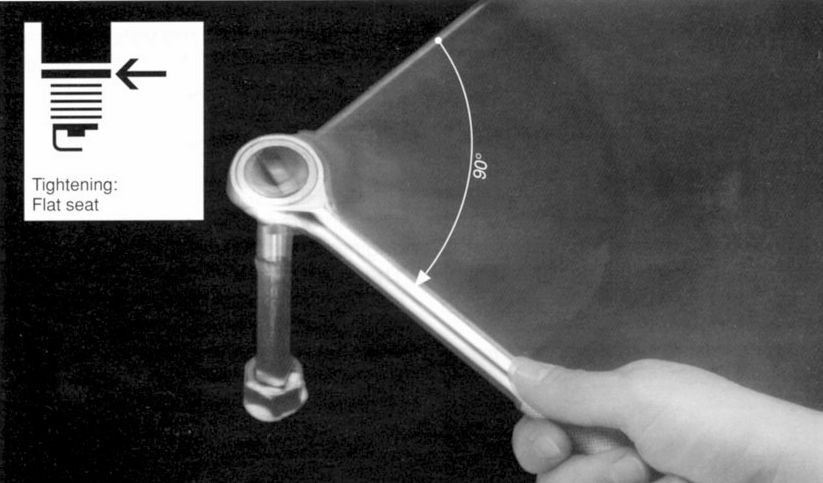

Adding The Right Amount Of Turn

Once the spark plug seats by hand, tighten it further by turning it a small amount. Usually, a quarter to a half turn past finger tight is enough. For plugs with a gasket, this crushes the washer to create a seal. For tapered seats, it helps the plug fit snugly. Tighten slowly and avoid applying too much force. Stop when you feel firm resistance to prevent over-tightening.

Estimating Torque Without Tools

Estimating torque without tools is useful when a torque wrench is unavailable. It helps prevent damage to spark plugs and engine parts. Applying the right tightness keeps the engine running smoothly. Below are two simple methods to estimate torque safely and effectively.

The Feel Method

Start by screwing the spark plug in by hand. Make sure it threads smoothly and seats firmly. Once seated, turn the plug about a quarter turn more. This small extra turn tightens the plug enough without overdoing it. You will feel resistance increase as you tighten. Stop turning when it feels snug but not forced. This method relies on your sense of touch and practice. It reduces the risk of stripping threads or cracking the plug.

Using A Lever And Scale

Use a simple lever, like a ratchet handle, and a kitchen scale to measure force. Attach the spark plug socket to the lever. Pull on the lever while the socket holds the plug. Place the scale under the lever’s handle to read the force applied. Calculate the torque by multiplying force by the lever length. This method gives a rough but useful torque estimate. It helps you tighten spark plugs closer to manufacturer specs without a wrench.

Tools Needed For Diy Spark Plug Installation

Installing spark plugs without a torque wrench requires the right tools for a safe and effective job. Having proper tools helps avoid damage and ensures the spark plugs fit securely. Gathering these tools before starting saves time and frustration. Below are essential tools needed for DIY spark plug installation.

Spark Plug Socket Options

A spark plug socket is a must-have tool. It fits over the spark plug and helps remove or install it easily. These sockets have rubber inserts or magnets to hold the plug firmly. Sizes vary, so check your spark plug size before buying. Common sizes include 5/8 inch and 13/16 inch. Using a deep socket is better to reach recessed plugs without damage.

Additional Helpful Tools

A ratchet wrench pairs well with the spark plug socket. It gives good control for tightening or loosening plugs. A flexible extension bar can help reach tight spots in the engine bay. A spark plug gap tool is useful to check and adjust the gap before installation. A feeler gauge or a small wire tool works well for this. A clean rag or compressed air helps clear dirt around the spark plug hole to avoid debris falling in.

Manufacturer Torque Specs

Manufacturer torque specs tell you how tight to fasten spark plugs. These specs prevent damage and ensure proper engine function. Following these numbers is important, even if you do not have a torque wrench. Knowing the right torque helps avoid over-tightening or under-tightening spark plugs.

Where To Find Specs

Check your vehicle’s owner manual for torque values. Manufacturers list exact numbers for each engine type. You may also find specs on the spark plug box or manufacturer’s website. Repair guides and online forums can be helpful too. Always verify with trusted sources to avoid mistakes.

Why Following Specs Matters

Correct torque prevents damage to the engine and spark plugs. Over-tightening can strip threads or crack the plug’s ceramic. Under-tightening leads to poor sealing, causing misfires or gas leaks. Proper torque ensures spark plugs seal tightly for optimal engine performance. It also helps maintain heat transfer and electrical contact.

Common Mistakes To Avoid

Tightening spark plugs without a torque wrench is possible but tricky. Many people make avoidable mistakes that can cause damage or poor engine performance. Learning common errors helps you protect your engine and get better results.

Using Power Tools Incorrectly

Power tools can tighten spark plugs too much. This often strips the threads or cracks the ceramic insulator. Over-tightening damages the aluminum cylinder head. It also makes future removal difficult and costly. Always avoid using drills or impact wrenches to tighten spark plugs. Instead, use hand tools and tighten slowly to feel the resistance.

Ignoring Thread Condition

Dirty or damaged threads cause problems when installing spark plugs. Old debris or corrosion prevents proper seating. This leads to poor compression and misfires. Always clean threads before inserting spark plugs. Check for any damage like cross-threading or wear. Damaged threads need repair or replacement to avoid leaks and engine issues.

Credit: forums.quattroworld.com

Tips For New Spark Plugs

New spark plugs need special care for the best engine performance. Proper preparation helps avoid engine problems and saves repair costs. Follow these simple tips before tightening spark plugs without a torque wrench. They make the process easier and safer.

Checking And Adjusting The Gap

Check the gap between the spark plug electrodes. Use a gap tool or feeler gauge for accuracy. The right gap size matches your engine’s requirements. Adjust the gap carefully by bending the ground electrode slightly. Avoid bending the center electrode. A correct gap ensures strong sparks and better engine running.

Cleaning Threads Before Installation

Clean the spark plug threads before installing. Dirt or old grease can cause poor contact or damage. Use a wire brush to remove dirt and old sealant. Make sure the threads are dry and free from oil. Clean threads help the spark plug screw in smoothly and tighten firmly.

Credit: www.youtube.com

Frequently Asked Questions

Do I Really Need A Torque Wrench For Spark Plugs?

Using a torque wrench for spark plugs prevents over-tightening or under-tightening, avoiding damage and ensuring proper engine performance. It guarantees the correct torque specified by the manufacturer, maintaining seal integrity and preventing misfires. For best results, always follow recommended torque specs during installation.

Can I Tighten Without A Torque Wrench?

Yes, you can tighten without a torque wrench using the “by feel” method, but it risks over- or under-tightening. A torque wrench ensures precise, safe torque, preventing damage and ensuring proper function. Always follow manufacturer specs for best results.

What Can I Use If I Don’t Have A Spark Plug Wrench?

Use a deep socket or adjustable wrench carefully. Hand-tighten the spark plug, then turn it an extra quarter to half turn by feel. Avoid over-tightening to prevent damage. A torque wrench remains the best tool for accurate tightening.

How Tight Should Spark Plugs Be By Hand?

Hand-tighten spark plugs until they seat firmly. Then turn an additional ¼ to ½ turn for proper snugness. Avoid over-tightening to prevent damage.

Conclusion

Tightening spark plugs without a torque wrench takes care and attention. Start by threading plugs by hand until snug. Then, turn the plug slightly more, about a quarter turn. Avoid forcing the plug too hard to prevent damage. Check your owner’s manual for specific advice.

Taking time ensures a good seal and engine performance. This simple method works well if done carefully and slowly. Always prioritize safety and proper technique over speed.