Common Problems With Jeep Wranglers Sway Bar – Easy Fixes

Sway bars are important because they stabilize your Jeep Wrangler in rough terrain and when driving through tough corners. Hence, faulty or problematic sway bars can make driving your Jeep a dangerous undertaking.

So, what issues can your Wrangler’s sway bar have? The two most common problems a Wrangler sway bar can develop are damaged bushings and faulty bar links. Damaged sway bars produce rattling sounds when the vehicle goes through corners or rough terrain.

Read on to learn more about common sway bar problems, their signs, and how to fix your vehicle if you ever damage its sway bar.

Table of Contents

What Is A Vehicle’s Sway Bar?

The sway bar or anti-roll bar is typically made of steel. It stabilizes the truck by reducing side-leaning and swaying while taking corners or going through rocky terrain. This stabilization is important because it stops the vehicle from overturning even when driving through steep places.

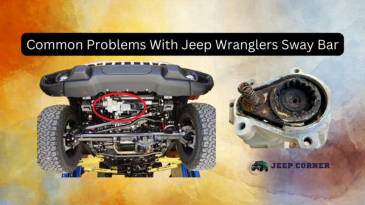

A sway bar is made up of sway bar links, bushings as well as the bar itself. The bushings connect the sway bar to the suspension, allowing it to move in tandem with the chassis. The bushing also reduces the noise and vibration caused by the vehicle’s movement.

Common Problems With Jeep Wranglers Sway Bar

Sway bars are made of bushings and bar links. These parts can fail due to various problems causing the sway bar to fail. Here are some of the problems that can affect a Jeep Wrangler’s sway bars;

- Bushing damage

Cracks in the sway bar bushings are one of the most common problems for Wranglers. They can also tear or wear out completely after long periods of use. Damaged bushings destabilize the sway bar, which in turn destabilizes the car.

The nature of bushings means that they cannot be repaired when damaged. Hence, if you notice the signs of damage, you should find replacements immediately. Fortunately, bushings are some of the cheapest car parts.

- Damaged sway bar links

Most Jeep Wrangler issues arise because of problems with sway bar links. Sway bar links are connected to the lower control arm beside the front wheels of the Wrangler.

Sway bar links often become damaged when they rust, age, or get overtightened. Lacking enough lubrication also causes the links to wear out more quickly.

What Are The Symptoms Of Problematic Sway Bars?

You will notice the signs if your Wrangler’s sway bar develops problems. Here are a few of those tell-tale signs;

- The Wrangler will handle poorly

Since the sway bar’s function is to prevent the truck from leaning sideways, any issue will increase the difficulty of steering. When you take corners or drive through rough patches, the weight of the Wrangler will regularly shift awkwardly. As a result, the truck will handle poorly.

Sometimes, the vehicle will feel unstable when you accelerate suddenly if the sway bar is compromised.

- Rattling sounds

Bad sway bar links make rattling sounds when driving over bumps or negotiating corners. You can hear these sounds more clearly when the front sway bar is faulty than when the rear sway bar is damaged.

When negotiating corners, the bar links take on most of the Wrangler’s weight because the truck’s weight naturally pushes outwards to the corner. Sway bars transfer weight from one side to the other and stabilize the vehicle, so they make lots of noise if damaged.

Driving a vehicle with a faulty sway bar can be dangerous. Fortunately, you can check the sway bar links while parked. Just turn your car’s steering wheel completely to the right and then to the left. If the sway bar is faulty, you’ll hear a clunking noise as you turn the steering wheel.

How To Troubleshoot Sway Bar Problems

If you notice signs that your Wrangler’s sway bar may be problematic, try and determine the issue. The following guide will help troubleshoot the issues;

- First Step: Cornering

The most obvious test of the sway bars is to drive around corners. When cornering, observe how the vehicle responds to your steering. If the sway bar is damaged, the vehicle will feel unstable. This instability results from the chassis moving side to side as you round the corner.

- Second Step: Listen for noises

Though there are sway bars on both the front and back end, you should listen for noises in the front one. The back-end sway bar can also make clunking noises, but it’s too far from you to hear properly.

If a sway bar component like the drop link is damaged, you’ll hear rattling noises as the vehicle turns around corners. Cracked bushings brackets will also cause some noise.

- Step Three: Remove the wheels

It’s wise to perform a visual inspection when you hear rattling sounds from the sway bars. The visual inspection requires removing the wheels to see the sway bar components. To do this;

- Unfasten the lug nuts that secure the wheels

- Use a jack to raise the vehicle. Ensure you support it properly with the appropriate jack stands.

- Remove the wheels to view the sway bar components

- Perform an inspection

Once the wheels are off, inspect the drop links. It’s easy to identify drop links since they are the short vertical parts that fasten the sway bar to the vehicle’s suspension. During your inspection;

- Ensure the bolts are fastened tightly.

- Check the drop link bushings for cracks and ensure they are not damaged or torn.

- Confirm that the drop links are intact with no breakages.

- Check the bushings that separate the sway bar from the vehicle frame for any damage.

How To Fix Sway Bar Issues

Some of the issues with sway bars can be fixed by cleaning and lubricating them. However, most problems require you to replace some sway bar parts. Here’s how to fix sway bar issues by replacing parts;

Sway bar links

Use the following guide to remove and replace damaged sway bar links;

- Get the right tools

Some tools and materials you’ll need are;

- Sockets

- New sway bar drop links

- Jack stands

- Jack

- Torque wrench

- Remove the damaged sway bar links

To replace sway bar links, use the following procedure;

- Ensure the parking brake is engaged and the rear wheels are chocked. Use the jack to raise the Wrangler and support it using the jack stand.

- Loosen the wheel lug nuts, but do not take them off completely.

- Carefully remove the lug nuts and wheels along with the tire assembly.

- With the wheel assembly out of the way, remove the sway bar starting with the links. Since Wranglers have bolt-type links, use the procedure below;

- Hold the link’s bolt using a wrench.

- Use the appropriate socket to remove the sway bar link nut.

- Pull out the bolt

- Finally, detach the sleeve.

3. Install the new links

Before installing the new anti-roll bar link, ensure it is the correct model and design for the Wrangler.

- After checking, slide the link’s bolt into the sleeve and ensure it slots into the control arm.

- Fasten the nuts to secure the link loosely

- Reinstall the wheel

- Tighten the lug nuts and lower the vehicle

- Once lowered, tighten the stabilizer link nuts using a torque wrench.

Sway bar bushings

To reach the bushings, you should follow the process below;

- Get the wheel out of the way

- Remove the wheel assembly.

- After removing the wheel, it’s time to remove the sway bar links. Use the same process described above to remove them.

- Take out the control arm’s mounting bolts.

- Use the appropriate wrench to unfasten the control arm’s mounting bolts. Before loosening the bolts, you need an extra wrench to secure the nut found on the opposite side. Ensure you hold the arm joints until you’ve removed all the bolts.

- Remove the control arm.

- After loosening the bolts, gently pull the control arm to detach it and reach the bushing.

- Replace the bushings

Follow the guide below to replace the bushing;

- Bushings attach to their outer metal rings in specific ways. Hence, before you remove the bushing, take note of its orientation.

- Unfasten the bolts of the old bushings

- Once the bolts are off, remove the metal bracket, followed by the rubber. The rubber may require prying off because it holds tightly.

- Pick the new bushing and spread it open. You can do this by inserting a metal bar and tilting it with considerable force.

- After you spread it open, push a smaller socket into the bushing. Force the bushing so it goes onto the sway bar from the socket.

- Line the bushing bracket into place and fasten its nuts to secure it.

Can you drive the Jeep wrangler without a sway bar?

Yes, you can, but that would be an uncomfortable ride without a sway bar since it’s what stabilizes your Jeep by reducing side leaning or swaying.

Can you drive the Jeep Wrangler with a bad sway bar?

Yes, you can. However, a bad sway bar will cause some swaying issues and will feel much like if you don’t have one. But that won’t affect your driving performance, especially if you drive with a minimized speed.

Conclusion

Like most car parts, sway bars inevitably develop problems due to age, rust, or other factors. If your Wrangler’s sway bar gets damaged, you’ll notice signs like rattling sounds and poor handling. Fortunately, sway bar problems are easily fixed by swapping out damaged parts like bushings.